OptimICE® is a liquid slurry ice technology that replaces conventional flake ice. The liquid slurry ice is produced on board the ship or onshore using seawater or saltwater. The liquid slurry ice surrounds the fish, quickly cooling it down below 0°C and keeping the temperature around -0.5°C. During the whole fishing trip, landing, during transport to manufacturers and at the final consumer the fish stays at the same temperature without freezing. Therefore, the cold chain never breaks with OptimICE® rapid cooling and the fish stays fresh at all times, maintaining maximum quality.

About OptimICE®

Where the cold chain never breaks

After 14 days of cooling

Flake Ice

OptimICE®

The difference in quality can be seen in the photos, taken of fish after fourteen days of cooling, where the right one is cooled with OptimICE® liquid ice and the left one with flake ice.

Rapid cooling of the catch is key

As soon as a fish is caught, its decay begins and the sooner it gets refrigerated, the less bacteria will grow, shelf life will be prolonged and maximum quality maintained.

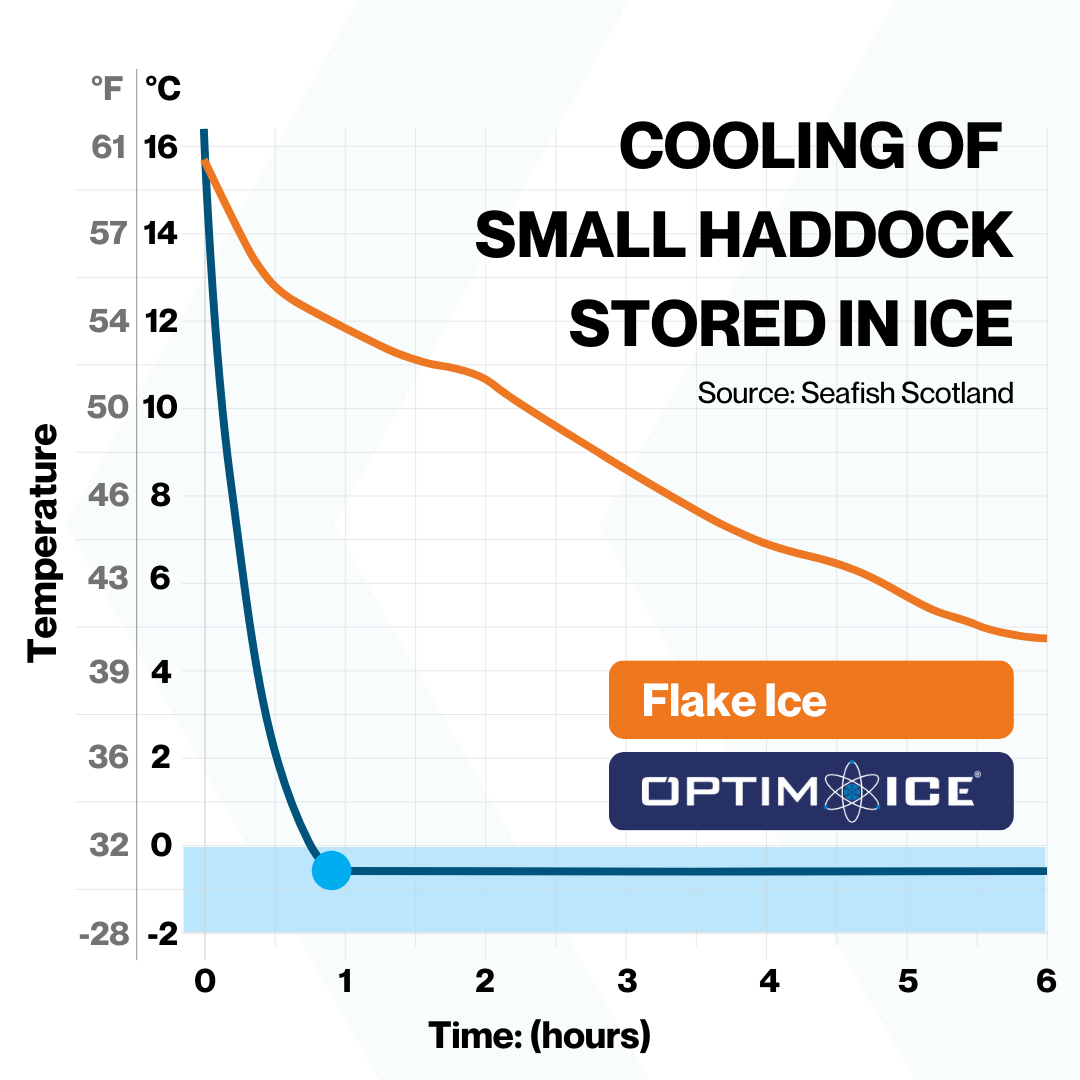

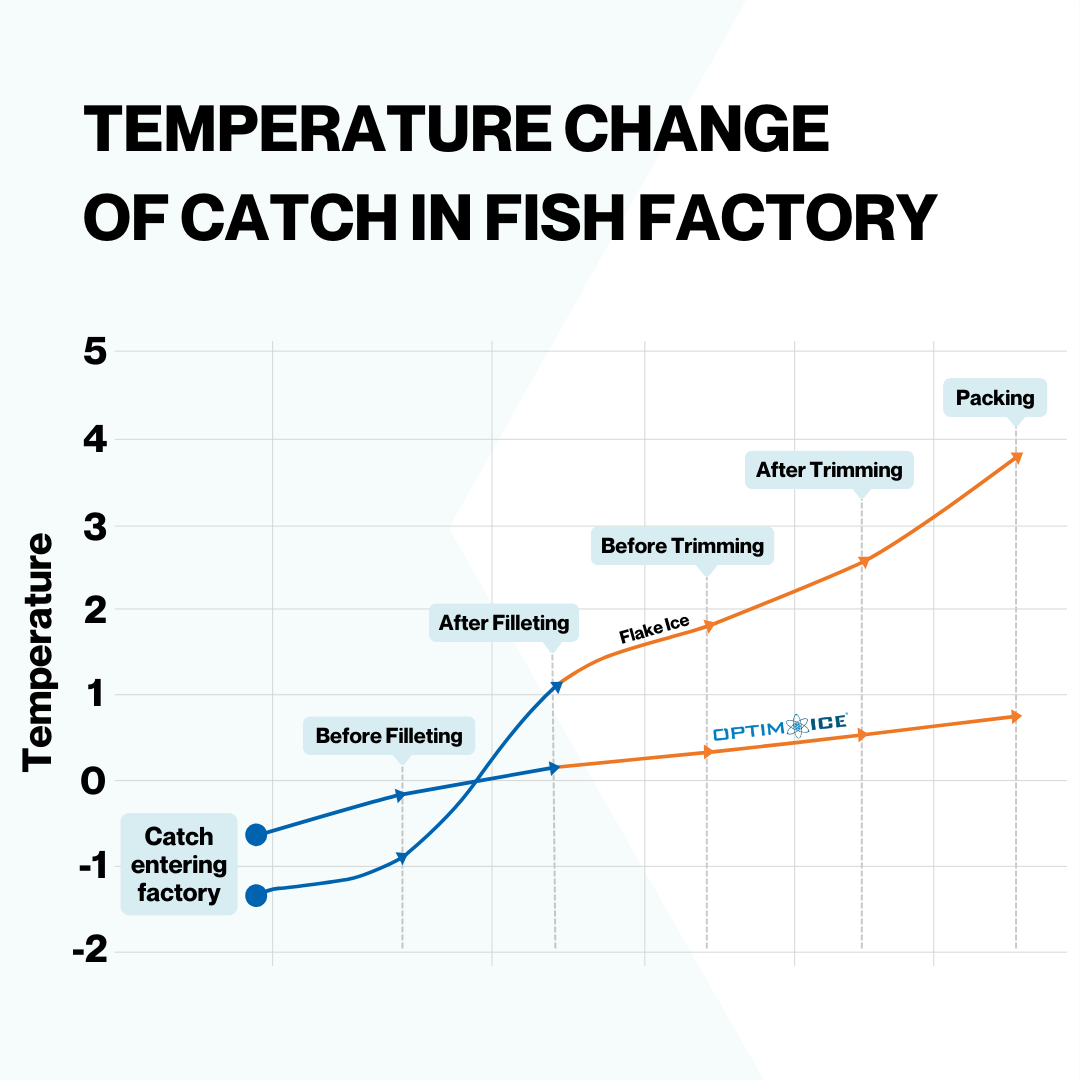

The graph shows the difference between cooling demersal fish with OptimICE® liquid ice on the one hand and traditional flake ice on the other.

Revolutionizing fish preservation

The OptimICE® liquid Ice system cools the fish down to below 0°C in less than one hour. Using traditional flaked ice, it takes around fifteen hours to reach the same temperature.

It is a recognized fact that treatment and cooling speeds are the most important in maintaining fresh fish quality. The key to increasing the quality of fish is rapid cooling, thus reducing microbial and bacterial formation.

Numerous studies have been performed on the cooling systems and all show similar results. The graph above is from Seafish Scotland. Matís, the Icelandic Food and Biotech research institute and the University of Akureyri as well as the International Journal of Refrigeration etc. have also researched slurry ice cooling and published similar results.

Fresh Product From Sea To The Consumer

The rapid and efficient cooling of the catch ensures the freshness and maximum quality of the product. The cooling never ends when the fish is in transport onshore. Even though cooling in a trailer fails, the cooling of the fish doesn’t stop because of OptimICE®.

The fish can finish the journey across the country and be complete and in top condition all the way, due to OptimICE®. The ice-less sub-chilling solutions are, on the other hand, very sensitive in transport.

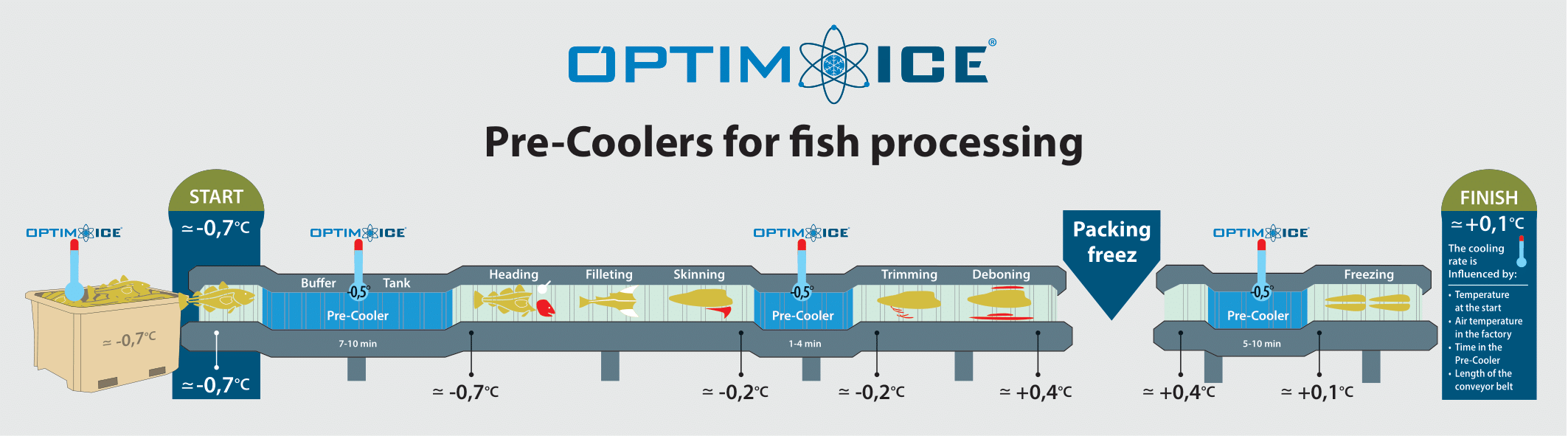

Temperature measurements

Temperature measurements were performed in a fish factory in Hellissandur where OptimICE® pre-cooling equipment is installed. OptimICE® liquid slurry ice machines are used on board the ships.

CO2 in all OptimICE® liquid ice machines

KAPP introduced an innovation for the fishing industry. It is a 100% CO2 refrigerant that will now be offered for the first time in all liquid ice machines instead of Freon.

We Are Trusted By

We are proud to share that our company has earned the trust of reputable industry leading companies. With a track record of reliability and excellence, we have established strong partnerships that rely on our products and services.

Over 800 vessels and food processing facilities use OptimICE®

Take a look at the OptimICE® family

Information

A guarantee is given for 12 months after test-run, or max 18 months from delivery of equipment from KAPP factory.

-

The guarantee covers only duplicate parts delivered EXW KAPP factory if failure is caused by original fault of material and/or workmanship.

-

The guarantee does not cover any leakage of refrigerant.

-

This guarantee is contingent upon the installation being approved and/or started by our supervisor at conditions agreed upon by the parties.

Let us help you optimice your quality

OptimICE® systems come in various types and they can be customized depending on your needs. We work closely with our customers to find the best solution for each operation.

Contacts

Cart

Your cart is empty